45 high pressure processing labels

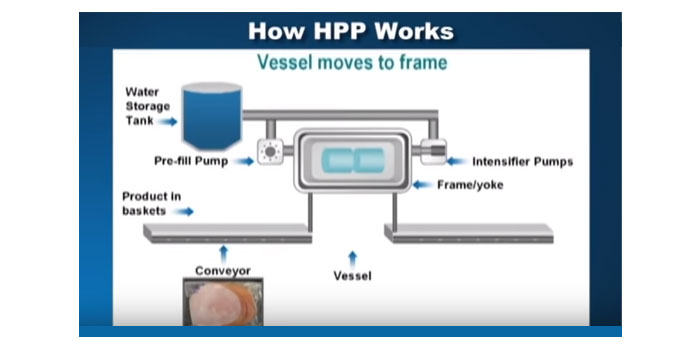

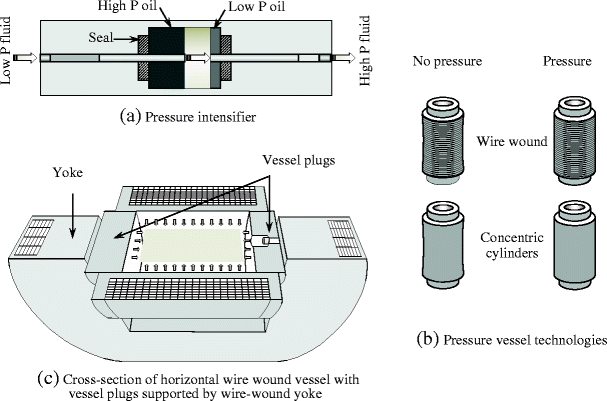

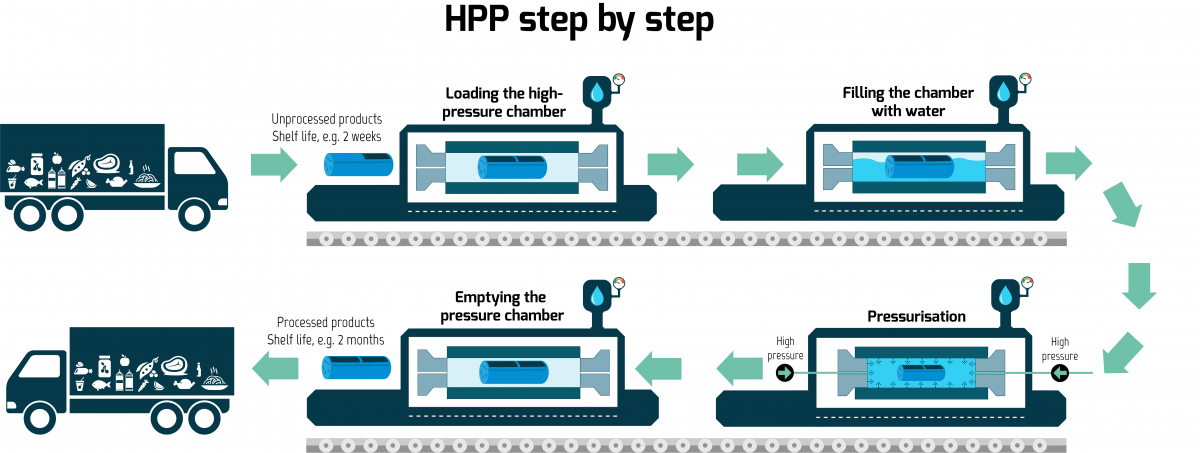

Process development of high pressure-based technologies for food ... Pressure-assisted thermal processing (or pressure-assisted thermal sterilization) involves pre-heating packaged food to an initial temperature (70-90°C), and subsequently subjecting the food to combined pressure-thermal treatment (400-600 MPa, at process temperatures >100°C) for a specified duration ().PATP is analogous to high temperature short time processing, wherein both pressure and ... High-Pressure Processing of Food: What You Should Know - Aptean.com High-pressure processing—also known by the acronym HPP and the term "pascalization" after the technique's inventor, Blaise Pascal— is the process of preserving and sterilizing food through the application of very high pressure, which leads to the inactivation of dangerous microorganisms and enzymes that may be present.

High pressure‐based hurdle interventions for raw and processed meat: a ... In the past decades, high-pressure processing (HPP) has been investigated as an alternative non-thermal preservation technology to match all these demands without compromising safety. HPP treatments could efficiently inactivate the vegetative microorganisms (related to foodborne diseases), but not spores.

High pressure processing labels

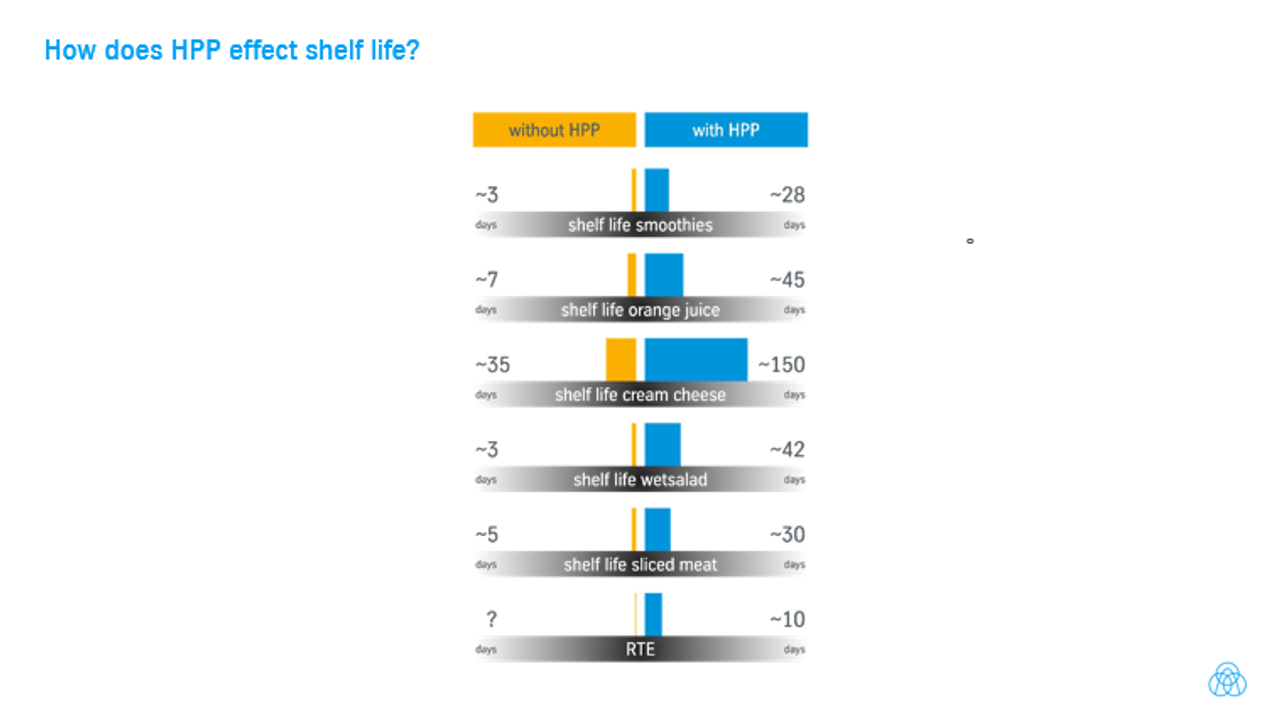

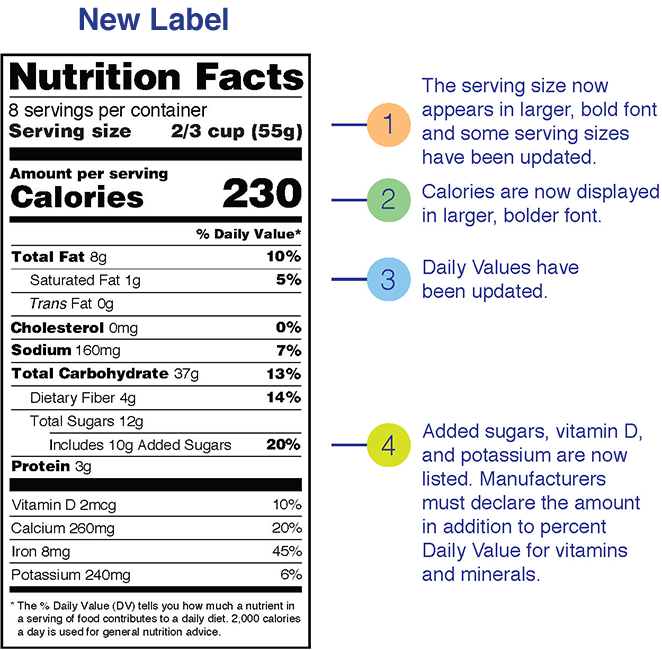

HPP: The Key Trends in High Pressure Processing High Pressure Processing (HPP) from JBT Avure is a technology that delivers significant product advantages for food and beverage processors, especially in shelf-life extension, food safety and the retention of flavor and nutrient content during pasteurization. But what are the top trends shaping its development industry-wide? Clean label processed meats: Australian industry says high pressure ... The Australian meat industry and state research body CSIRO believe that high pressure processing (HPP) tech is the way forward to create truly clean label processed meat products such as sausages and hams, though current high cost hurdles still prevent this from becoming mainstream. Should you use high-pressure processing for your pet food? Once the maximum pressure level is reached, bacterial inactivation occurs and the pressure is released. After high-pressure processing is complete, the product can be sold refrigerated or frozen, or further processed into other products. 5 benefits of HPP Serment-Moreno outlined five main benefits of using HPP for raw pet food products:

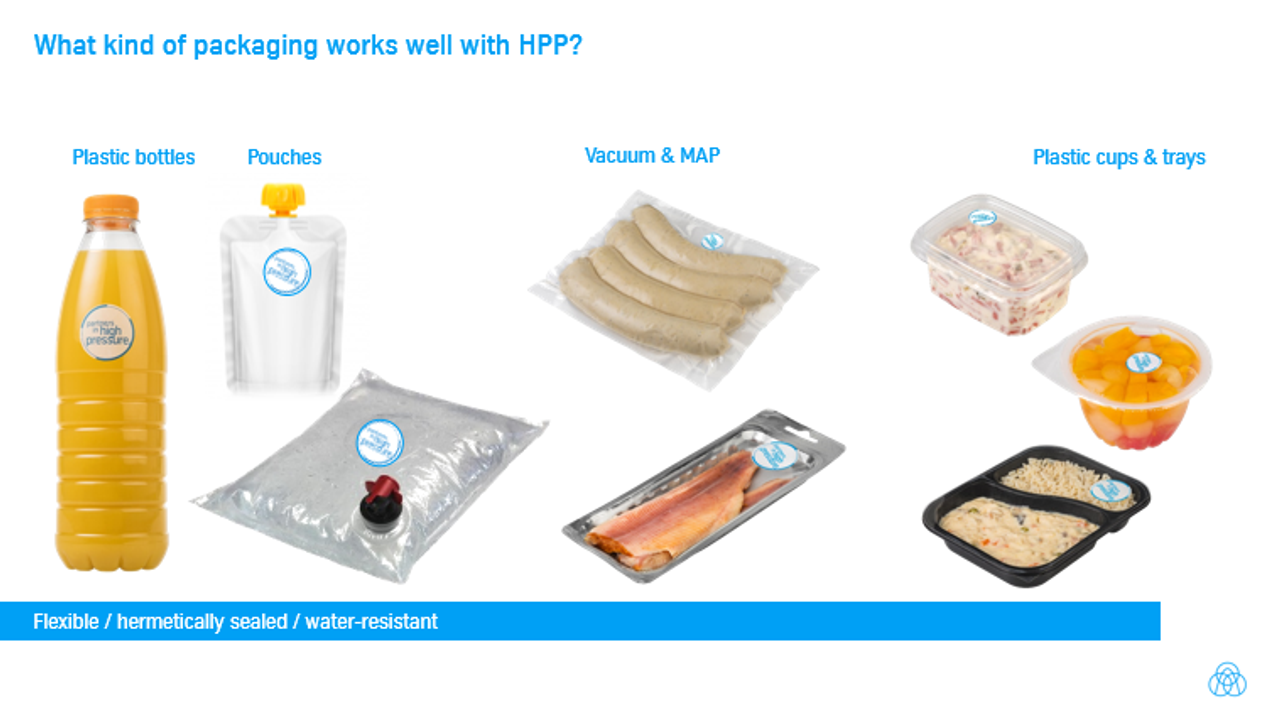

High pressure processing labels. HPP milk concerns flagged as EFSA endorses high pressure processing for ... High pressure processing is regarded as a natural way to preserve food and drink products without the use of additives, thus appealing to clean label demands. Image: Getty/Fahroni. Related tags: Hpp, Clean label, Milk High-Pressure Processing: How Does It Work? - Beyond The Magazine High-Pressure Processing: How Does It Work? This food process begins by placing deli meats in flexible, water-proof packaging. From there, these packages then enter a high-pressure vessel. Next, the vessel fills with water and becomes pressurized to 6,000 bar. This process works instantaneously and identically across several types of food. High-pressure processing will grow by 25% in food and beverages by 2022 Cold Pressure or high pressure processing prolongs the shelf life of foods, maintaining their nutritional and sensory characteristics and eliminating the use of additives and colorants. This processing method responds to the five key consumer trends that demand clean label, ready-made, long lasting, sustainable, safe and better preserved products. U.S. High-Pressure Processing Market is growing at a CAGR of ... - FMIBlog FMI forecasts the global high-pressure processing equipment market to witness a CAGR of over 13 % in terms of value and a CAGR of 12.3% in terms of volume between 2016 and 2026. The US$ 133.5 Million HPP equipment market is estimated to create an incremental $ opportunity of over US$ 350.5 Million during the assessment period.

High‐pressure processing of fish and shellfish products: Safety ... Abstract Seafood products have been one of the main drivers behind the popularity of high-pressure processing ... overview of the advanced knowledge available on the use of HPP for production of wholesome and highly nutritive clean label fish and shellfish products. Out of 653 explored items, 65 articles published during 2016-2021 were used. ... Equipment for high pressure processing, market size set to increase ... Equipment for high pressure processing, market size set to increase past USD 430 Million The global high pressure processing equipment market size is anticipated to surpass the value of USD 430 Mn, while recording a CAGR of 12.3% in terms of volume from 2016 and 2026, and at a value CAGR of 13.7% during the same time period. On Sep 8, 2022 High Pressure Processing Equipment Market Research, Segmentation, Key ... the size of the global high pressure processing equipment market is anticipated to exceed usd 430 million, with a volume cagr of 12.3% between 2016 and 2026 and a value cagr of 13.7% over the same period.the adoption rate of hpp equipment for cold pasteurisation in f&b industry is one the major parameters based on which the global market size has … EOF

High-pressure jet processing of chocolate milk may reduce the use of ... Because the use of high-pressure jet technology to improve the dispersion stability of cocoa provides the industry with a processing alternative to produce clean label, yet stable, low-fat... High-pressure processing enhances food safety, extends shelf life Among the benefits of high-pressure processing are food safety, clean label, enhanced flavor, taste and nutrition, and shelf life extension, Hiperbaric's Roberto Peregrina says. Image courtesy of Hiperbaric USA "This reduces downtime and maintenance cost while increasing equipment lifespan and production capacity," Bros explains. High Pressure Processing - Agricos Library - Agricos Library High Pressure Processing. High Pressure Processing is a non-thermal, environmentally friendly process that allows the development of juices and beverages with fresh-like organoleptic quality and nutrition, while extending the shelf life of the product. History High pressure processing (HPP) vs traditional shelf-stable methods High pressure is applied to the product in its final package that prevents post-processing contamination, reducing or eliminating the need for additives, inactivates microorganisms increasing food safety and extending the shelf life up to 10 times longer. Thus, HPP increases brand protection and allows to enter new markets.

How Does a Pressure-Sensitive Label Get on a Package? The nip-and-pressure roll pulls the web through the labeler. The empty web is collected on the rewind reel. The process is started when a sensor detects the product. This starts the nip roller pulling the web, dispensing the label. The label sensor detects the gap between labels and stops the nip roller when the label is fully dispensed.

Should you use high-pressure processing for your pet food? Once the maximum pressure level is reached, bacterial inactivation occurs and the pressure is released. After high-pressure processing is complete, the product can be sold refrigerated or frozen, or further processed into other products. 5 benefits of HPP Serment-Moreno outlined five main benefits of using HPP for raw pet food products:

Clean label processed meats: Australian industry says high pressure ... The Australian meat industry and state research body CSIRO believe that high pressure processing (HPP) tech is the way forward to create truly clean label processed meat products such as sausages and hams, though current high cost hurdles still prevent this from becoming mainstream.

HPP: The Key Trends in High Pressure Processing High Pressure Processing (HPP) from JBT Avure is a technology that delivers significant product advantages for food and beverage processors, especially in shelf-life extension, food safety and the retention of flavor and nutrient content during pasteurization. But what are the top trends shaping its development industry-wide?

Post a Comment for "45 high pressure processing labels"